CAD software provides accurate designs for practical injection molding and extrusion for creating parts and tools. While designing your extrusion tool, you factor in thickness, tool design, and dimensions. Here are some uses of CAD software in plastic extrusion:

Creating Designs

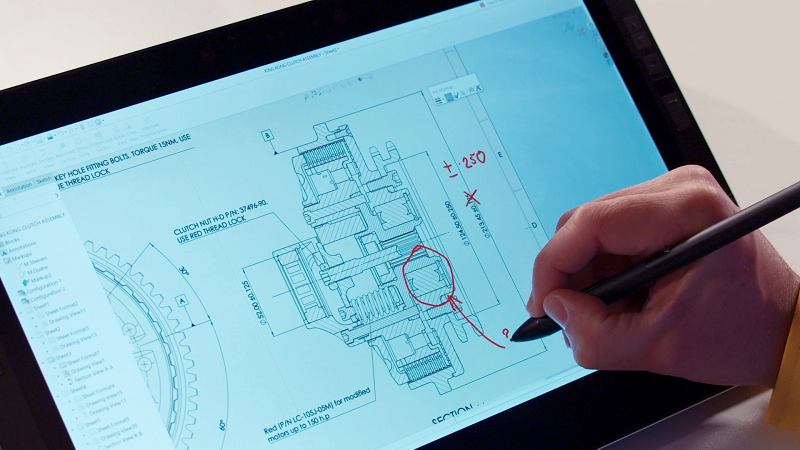

CAD software allows designers to make accurate and detailed designs for extrusion tools. The software helps to create precise and consistent products due to dimensions and measurement capability. It can also quickly make modifications or adjustments when necessary, saving time and reducing errors in situations that require different tool designs for each stage of the extrusion process.

Simulating the Extrusion Process

Designers can use CAD software to simulate the plastic flow within a specific extrusion process for the best results. This allows them to identify potential problems and make necessary adjustments before manufacturing, reducing production delays. Simulations provide designers with the ideal temperature, pressure, and speed conditions for the best products. The ability to visualize the extrusion process also makes it easier to identify and fix potential issues.

Creating Prototypes

Prototyping allows for testing and inspecting the product design visually and practically before the final manufacturing. Using CAD software makes it easier to develop real-life sizes and prototypes. It will help the designers assess issues with wall thickness, dimensions, and surface finishing. This aids in confirming that the final objectives and goals of the clients have been met. You can make more than one prototype of a product from different materials to test the efficiency of the materials before deciding on which one to use on the final product during mass production.

Generating Tool Paths

CAD software allows the development of paths through which an extrusion machine will manufacture a product. When a proper tool path is followed, the designer can generate products with accurate measurements. CAD software also allows the designer to refine the tool paths concerning certain needs or better designs for manufacturing.

Supporting Product Personalization

Communication-aided design software helps modify existing designs or create other unique products. This is useful in industries with customers whose demands vary from one time to the other. It enables immediate design changes and generates its products to suit the market and pressure from competitors. CAD software allows for effective teamwork between designers and customers. You can discuss its designs and get feedback immediately, which will help you avoid wasting time on product satisfaction.

Integration with other Software

Plastic extrusion involves several other software programs in its production process, such as simulation software and costing tools. CAD software can integrate these programs to make the production process smoother and more efficient. This leads to good communication and coordination between different departments and technologies. Integrating different software that can integrate leads to more accuracy in your product creation. and better overall efficiency in production.

Optimizing Plastic Extrusion Processes

Incorporating CAD software into plastic extrusion workflows enables designers to simulate the production process before it takes place. This helps identify and resolve potential issues during production, saving time and resources. Contact a CAD software provider to learn more about optimizing plastic extrusion processes with their tools.