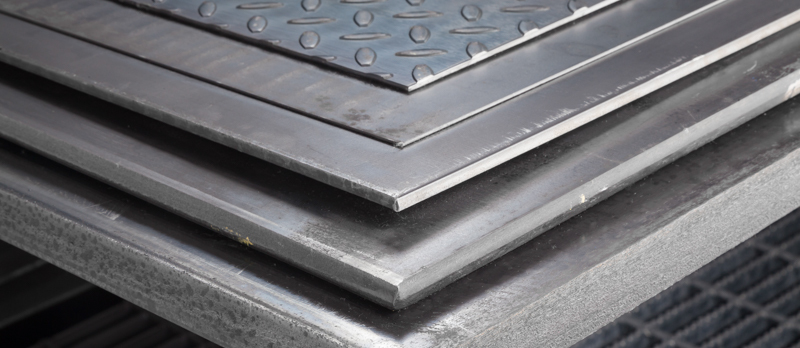

In the world of industrial uses, sheets, and plates are basic materials that are used for a wide range of tasks. The grade of material used in Inconel 600 Sheets and plates is very important for performance, durability, and cost-effectiveness in many industries, from building and manufacturing to aerospace and automotive. This complete guide talks about how important it is to choose the right material grade, contrasts the different grades that are usually used in factories and shows what each grade is used for.

Importance Of Material Grade Selection

Choosing the right type of Inconel 601 Sheets or plate is very important because it has a direct effect on how well industrial structures and parts work and how long they last. The primary factors considered when choosing a material grade include:

Mechanical Properties: Different grades offer varying strengths, ductility, hardness, and other mechanical properties tailored to specific operational requirements.

Corrosion Resistance: In places with a lot of water, chemicals, or heat, corrosion protection is very important.

Weldability And Formability: Ease of fabrication, welding, and forming capabilities influence manufacturing processes and operational efficiency.

Cost Considerations: Balancing performance requirements with material costs is crucial for maintaining competitiveness and optimizing project budgets.

Common Grades Of Sheets And Plates

1. Carbon Steel

Due to their flexibility and low cost, carbon steel sheets and plates are some of the most common materials used in industry. Grades such as ASTM A36, A572, and A516 are common choices for structural components, machinery parts, and general fabrication due to their moderate strength and excellent weldability.

2. Stainless Steel

People love stainless steel because it doesn’t rust and looks good. This makes it perfect for uses that need to last in harsh settings. Grades like 304 (L) and 316 (L) are chosen in places where cleanliness and resistance to corrosion are very important, like food processing, pharmaceuticals, and marine environments.

3. Aluminum Alloys

In the aerospace, automotive, and building industries, aluminum alloys offer solutions that are both light and strong. Grades like 6061 and 7075 are known for having a high strength-to-weight ratio, being easy to machine, and not rusting. This means they can be used for accurate machining and structural parts.

4. High-Strength Low-Alloy (HSLA) Steel

HSLA steels combine enhanced mechanical properties with reduced weight compared to traditional carbon steels. Grades like ASTM A572 and A656 offer superior strength, toughness, and weldability, making them suitable for heavy equipment, bridges, and structural applications where weight reduction is advantageous.

5. Titanium Alloys

Titanium alloys are prized for their exceptional strength-to-weight ratio, corrosion resistance, and high-temperature performance. Grades such as Ti-6Al-4V find applications in aerospace, medical implants, and chemical processing where lightweight, durable materials are essential.

Applications Across Industries

Each grade of Monel 400 Sheets and plate finds unique applications based on its specific properties:

Construction: Carbon steel and HSLA grades are used in building structures, bridges, and infrastructure due to their strength and durability.

Automotive: Aluminum alloys and high-strength steels contribute to lightweight vehicles while maintaining safety and fuel efficiency.

Aerospace: Due to their great strength, resistance to heat, and low density, titanium alloys are used to make important parts of airplanes.

Oil & Gas: Stainless steels and corrosion-resistant alloys withstand harsh environments in offshore drilling platforms and pipelines.

Future Trends And Innovations

As industries evolve, materials science continues to innovate with advanced alloys, composites, and sustainable materials. Emerging trends include:

Advanced High-Strength Steels (AHSS): Offering superior strength and formability for automotive lightweighting.

Nanostructured Materials: Enhancing mechanical properties and corrosion resistance through nanotechnology.

Recyclable Materials: Increasing focus on eco-friendly alloys and composites to reduce environmental impact.

Conclusion

Choosing the right grade of sheets and plates for industrial applications requires careful consideration of mechanical properties, corrosion resistance, and cost-effectiveness. Each material grade brings unique advantages suited to specific operational requirements across diverse industries. By staying informed about advancements in materials science and understanding the nuanced differences between grades, industrial stakeholders can optimize performance, enhance durability, and drive innovation in their respective fields.

To sum up, choosing sheets and plates based on the grade of the material is a very important choice that affects how well, reliably, and long-lasting industrial uses work. Businesses can make decisions that meet their operational needs and strategy goals if they know about the properties and uses of different grades.